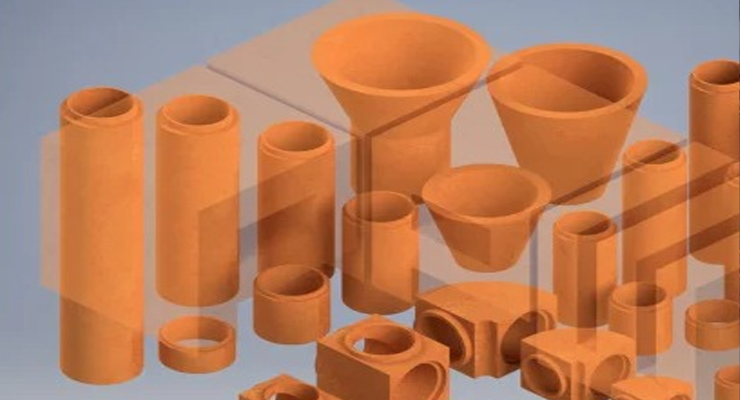

Casting Refractory

Casting Refractory can be used to create the monolithic linings within all types of furnaces and kilns. They can be further classified into the following sub-categories: conventional, low iron, low cement, and insulating for installation either by gunning or manually.

L-type casting refractory Is materials are specifically designed for applications requiring linear configurations or channels in casting processes. These materials offer excellent thermal stability, erosion resistance, and dimensional accuracy, ensuring precise control over metal flow and solidification during casting operations.

T-type casting refractory products feature a T-shaped configuration, making them suitable for bifurcating or branching channels in casting systems. These refractories provide reliable performance in directing molten metal flow, minimizing turbulence, and promoting uniform solidification, thereby enhancing casting quality and efficiency.

K-cut casting refractory shapes are engineered with specialized geometries to facilitate precise cuts or openings in refractory linings. These shapes enable operators to customize the configuration of ladles, tundishes, and molds according to specific casting requirements, optimizing metal flow patterns and minimizing casting defects.

General Specifications :

| Composition | Color | Density (gm/cc) | Thermal Conductivity (W/mK) | Maximum Service Temperature | Application Method |

|---|---|---|---|---|---|

| High-grade Refractory Aggregates, Binders, and Additives | Off-white | 2.2-2.5 | 1.5-2.0 | 1600°C | Suitable for Casting using traditional molding techniques or advanced refractory casting methods |